ESP500A Epassport Sheet Punching Machine is suitable for punching position holes in epassport materials. The Sheet Punching Machine is an essential tool for addressing the epassport solution with precision and efficiency. According to different passport lamination positioning requirements, the corresponding positioning process holes can be punched on the epassport material before lamination.

| Capacity | 500UPH |

| Application Materials | PVC Film |

| Dimension | 2670×870×1900mm |

| Weight | 1100kg |

| Power Supply | 220V |

| Noise | ≤65dB |

| Operation Temperature | 23℃±3℃ |

| Operation Humidity | 50±10%rh |

| Compressed Air | pressure:0.6Mpa |

| Communication Interface | None |

1. Configure a material magazine.

2. The material magazine capacity is 1,000 sheets.

1. Configure a Cartesian coordinate manipulator.

2. Vacuum grabbing materials.

3. Pneumatic splitting ensures that one piece of material is captured each time.

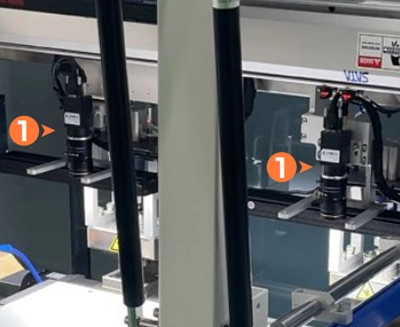

1. 2 Visual cameras.

2. Two positioning ways: Mark point of PC

3. material and edge of PC sheet.

4. Positioning accuracy: ±0.04mm.

5. Vacuum adsorption and fixation of PC sheets.

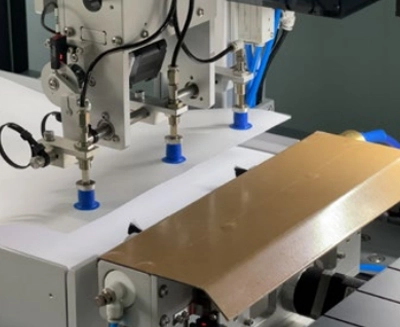

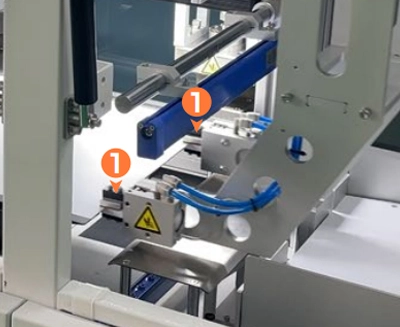

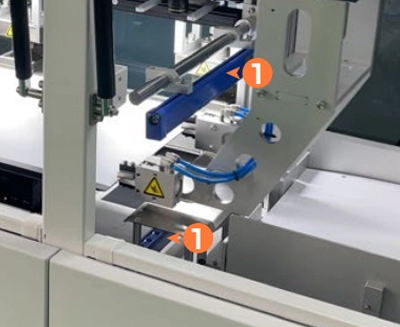

1. Each piece of material has 2 circular positioning holes with a diameter of 6mm+0.05mm

2. Customized positioning hole punching molds.

3. Connect an industrial vacuum cleaner below the punching module to suck away the waste material from punching hole.

4. The mold replacement time is ≤30 minutes.

The module adopts a OCR system that can accurately identify hole position, hole size accuracy, and puching hole effect (whether there are burrs, cracks, etc.).

1. Configure a Cartesian coordinate manipulator.

2. Pneumatic gripper grabs materials.

3. Sort pass/fail based on the results of visual re-inspection.

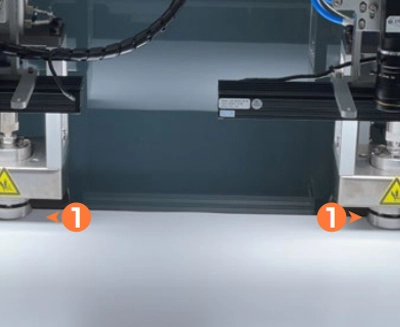

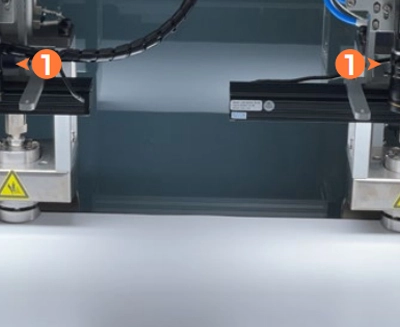

1. Clean the upper and lower sides of the entire width to ensure that there is no dust and impurities on the upper and lower surfaces of the material.

2. Using front and back ion wind to eliminate static electricity and remove dust and impurities.

1. The output magazine stores finished materials, with a size of 500*330mm.

2. When the number of materials collected in the output magazine reaches 500, it will be suspended and the production perrsonnel must be notified to collect materials.

The manipulator must be able to position at the micron level of accuracy to ensure that the position of each hole is accurate. And maintain stability and consistency in high frequency operation.

E-passport materials can be very thin and easily damaged. The manipulators need to have flexible handling capabilities to avoid damage to materials during take-up and discharge.

Advanced robotic systems may integrate visual recognition technology to identify the position and orientation of materials and perform real-time calibration. This requires high-resolution cameras and fast image processing algorithms.

Contact Piotec for Smart Card Solution