To meet high-volume personalization production for SIM cards with multi-chips, PTA-8500A smart card making machine was developed and put into the market in 2015. The PTA-8500A smart card making machine can perform high-volume various SIM card personalization including chip encoding, laser marking, and card surface information verification.

With more than 100 sets delivered and proven by the market for over 8 years, PTA-8500A has become the mainstream SIM card personalization equipment. As a SIM card manufacturing machine, our card personalization machine such as PTA-8500A serves the most famous SIM card manufacturers in China and even in the whole world.

| Capacity | 6000UPH |

| Dimension | 3600mm×910mm×1900mm |

| Weight | 800kg |

| Power Supply | 220V (-5%~+10%) 50Hz 6KW |

| Noise | <65dB |

Operation Temperature | 23℃±3℃ |

| Operation Humidity | 50±10% |

| Compressed Air | Pressure: 0.5Mpa Flow: 400L/min |

| Communication Interface | Ethernet |

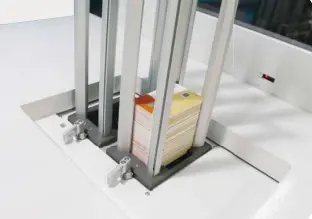

1. Equipped with 2 removable input magazines with maximum capacity of 500pcs for each.

2. Automatic magazines exchange, chip absence and double-card detection can be realized.

1. Standard configuration: 32 contact IC perso stations with 64 perso heads and 16pcs of PIOTEC 4IN1 contact readers PT204PT-AMA.

2. Extensible configuration: 64 perso stations with 384 perso heads and 96pcs of PIOTEC 4IN1 contact readers PT204PT-AMA.

3. ISO cards, 2IN1, 4IN1 or 6IN1 cards can be persoed to meet customers' requirements for high compatibility and productivity.

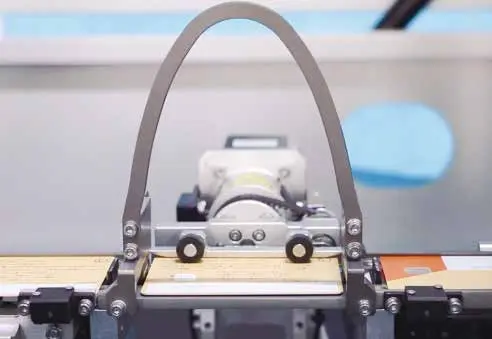

1. Equipped with 4 sets of flipping mechanism.

2. Double-sided marking and card output side changing can be realized.

1. Equipped with 2 sets of high-speed laser marking modules.

2. Equipped with 2 sets of 50W fiber lasers.

3. Equipped with 2 extractors.

4. Uninterrupted laser marking and flexible configurable dual laser serial and parallel marking can be realized, which improves marking efficiency.

1. Equipped with 1 set of 5 million pixel of industrial camera (including light source).

2. Equipped with 1 set of OCR software.

3. Card surface information (Digital number, Barcode, QR code, 25 code) can be recognized and verified.

1. Equipped with 2 removable output magazines with maximum capacity of 500pcs for each.

2. Automatic magazine exchange and fullness detection can be realized.

High-volumn of personalization production for ISO, 2IN1, 4IN1, and even 6IN1 card.

To connect with Milling, Embedding, Punching, and Labeling machine id into SIM card smart production line.

The patented technology of static perso tower ensures that the rejected rate is less than 1/1000.

The more than 10 years of proven PIOTEC industrial-grade reader ensures the stability and efficiency of chip encoding.

One operator can operate and manage 3~5 PTA-8500A at the same time.

The patented high-speed laser marking technology enables the laser marking uninterruptedly so that the utilization rate of lasers is up to maximum.

One-button switching between orders with different card specifications(such as between 2in1 and 4in1 cards) in the software is available, which largely reduces the order switching time.

The maximum production capacity of the PTA-8500A SIM card maker reaches 36,000 chips/h, which improves the factory's income.

The data perso system has been proven by the market for more than 10 years.

The cards that failed to be encoded or marked can be automatically rejected and re-made online.

The OCR ensures that the information on the card surface is accurate.

Secondary development is fully supported to meet various customized data security needs.

Contact Piotec for Smart Card Solution