PTM-120T can be integrated with short-circuit punching, open and short tests, chip initialization & pre-personalization as well as reject chip punching and marking. The brand-new design enables operators to switch chip production between 6PIN and 8PIN within 60 seconds.

As a smart card personalization machine, PTM-120T can be applied to contact/contactless and dual interface chip initialization, and also can be customized according to the demands for various chip production.

| Capacity | 53000UPH |

| Dimension | 4750mm×840mm×1960mm(including broken reinforcement units); 3800mm×840mm×1960mm(excluding broken reinforcement units) |

| Weight | 800kg (including broken reinforcement units); 650kg (excluding broken reinforcement units) |

| Power Supply | 220V (-5%~+10%) 50Hz 4KW (including broken reinforcement unit); 220V (-5%~+10%) 50Hz 2KW (excluding broken reinforcement units) |

| Air Supply | No air source required |

| Noise | <50dB |

| Operation Temperature | Room temperature: 23℃±3℃ |

| Operation Humidity | 50±10% |

| Maximum Throughput | 60,000 UPH (including broken reinforcement units); 120,000UPH (6PIN, excluding broken reinforcement unit) |

| Short-circuit Punching Throughput | Maximum production capacity 60000 UPH (14 pieces per round) |

| Chip Module Specification | M2, M3 |

| Communication Interface | Ethernet |

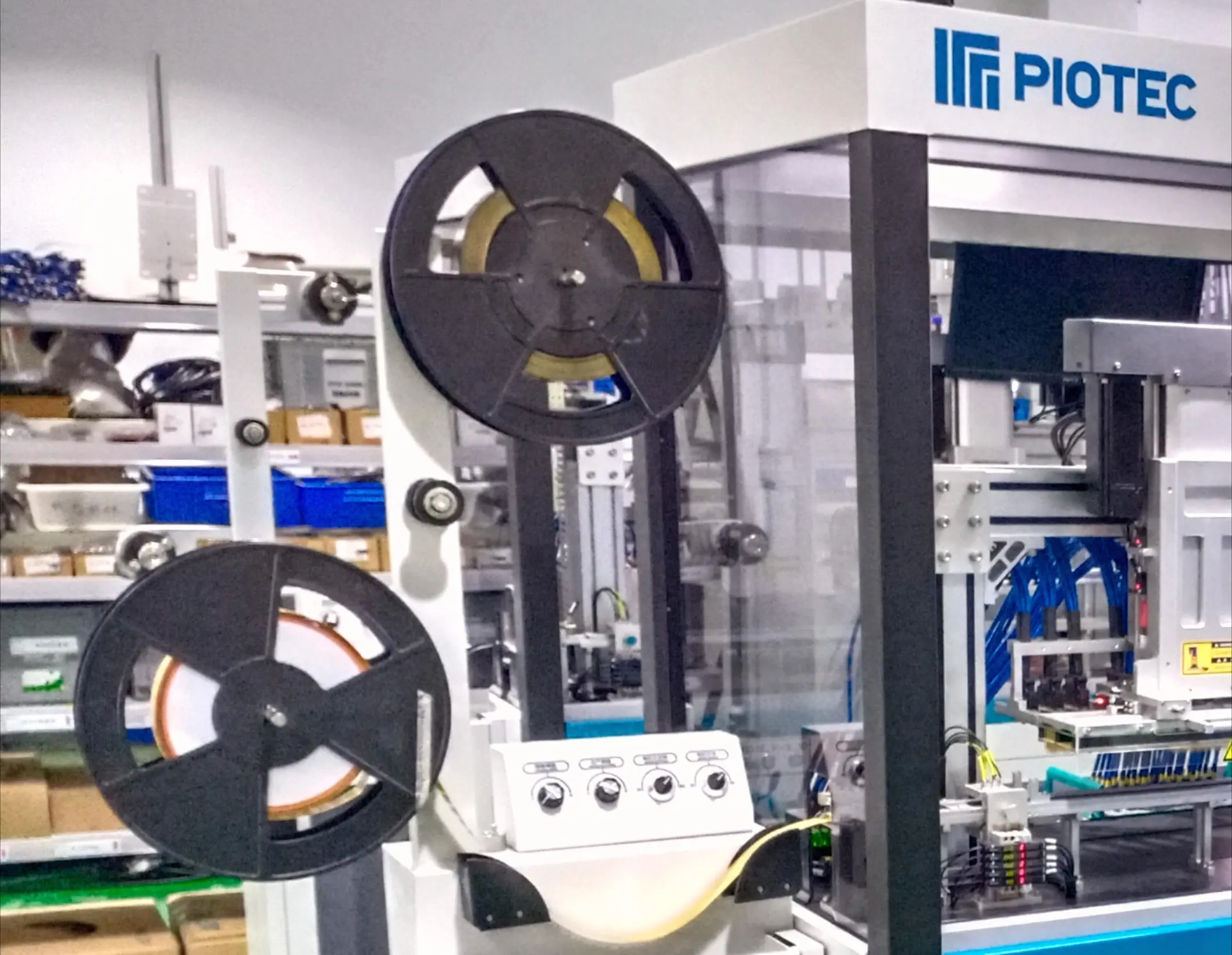

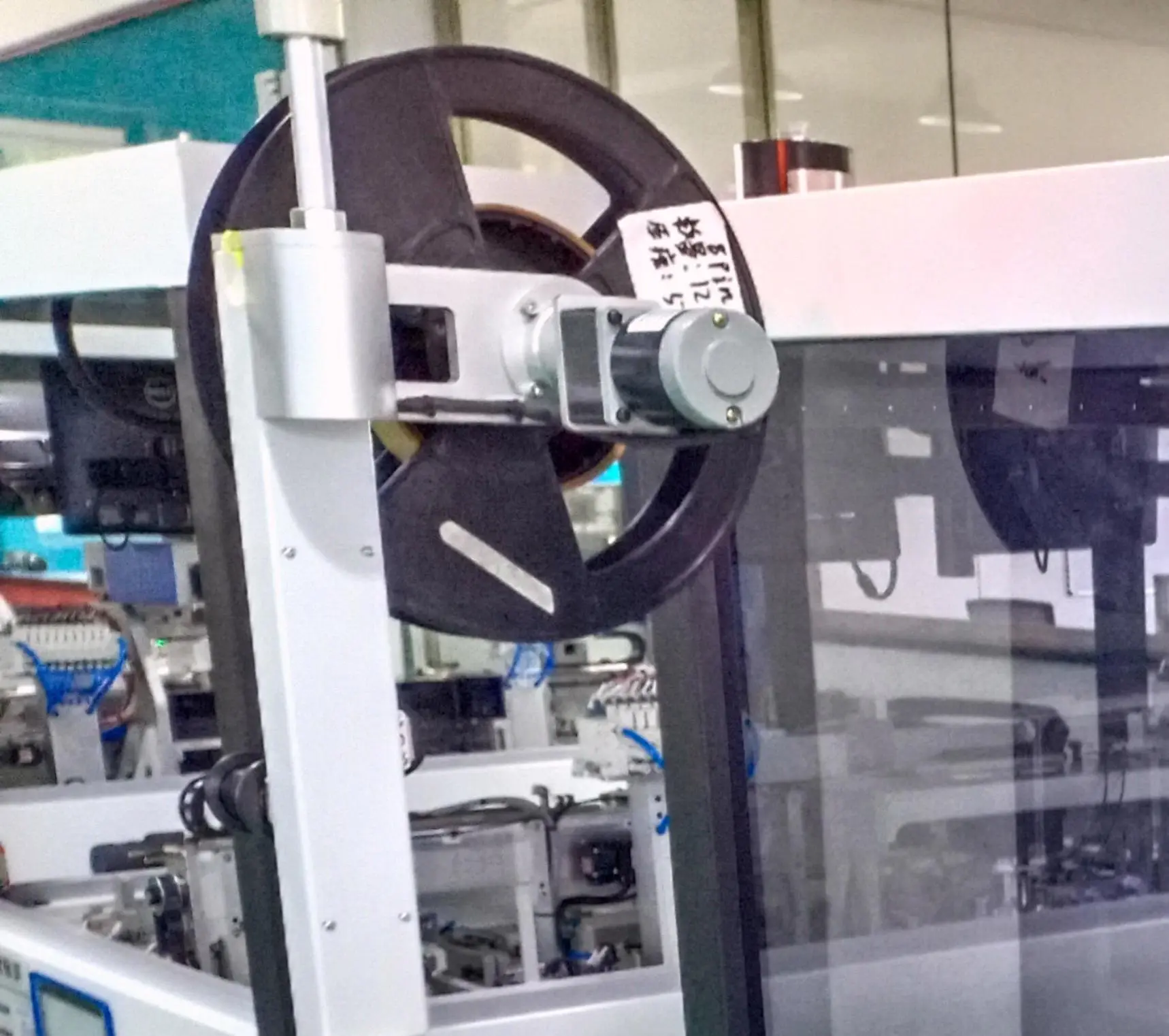

The position adjustment of the active and driven material trays is convenient and can adapt to different incoming directions; Compatible with 12.6MM and 38MM shaft diameter material trays.

Compatible with 6PIN and 8PN chip production; Supports up to 120 contact test heads and 12 non-contact test heads simultaneously for electrical performance testing and data writing of contact, non-contact, or dual interface modules; Alternatively, 60 contact test heads and 60 non-contact test heads can be configured according to customer requirements. This unit can work independently.

Configure 2 sets of contact test heads or 3 sets of non-contact test heads to automatically write/test failed chips, minimizing waste.

The identification of punch holes for chips that have failed to write or test can be flexibly set through software without the need for manual adjustment, greatly improving the accuracy and production efficiency of punch holes; This unit can work independently.

Roll up the written and tested strips and wrap them with protective tape; This unit can work independently.

Capable of cutting the connecting ribs of chip strips; By changing the mold, it is easy to cut different specifications of chip strips; This unit can work independently.

The equipment is compatible with 6pin and 8pin module strip production.

Unique patented technology for fast switching of chip types: It can quickly switch between 6pin and 8pin production tasks within 60s without removing and inserting cables.

Max.throughput 100,000cph for 6PIN chip;

Max.throughput 77,000cph for 8PIN chip.

The top industrial-class reader developed by Piotec with open/short test function is stable and high cost-effective.

Independent side hole visual detection module can carry out high-speed and high-precision real-time detection of side holes and waste holes to ensure the accuracy and precision of side hole detection.

The flexible testing scheme is suitable for different IC module applications.

Independent punching mechanism can accurately set the punching position of double row chip through parameters (XY direction can be used), without adjusting the position of mechanical structure, high precision and good punching consistency.

Free of production site due to electric driving design without external air supply.

Open-short test for pins (positive and negative current is adjustable).

Leakage current test supported.

Static current test supported.

FVMI and FIMV (V=f(I), I=f(V)) supported.

Pin voltage value of Vih and Vil is Adjustable.

Contact Piotec for Smart Card Solution