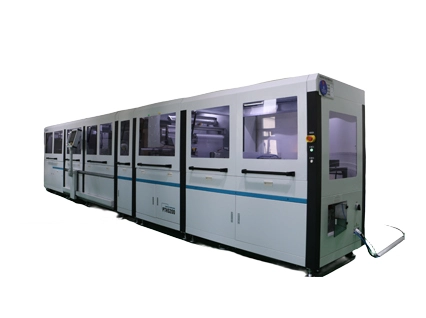

On April 29th, the Desktop Smart Card Personalization Machine PTH-1502 has passed the layers of quality inspection, and will start a new journey across the ocean to our European customer! Let's review what "assessments" that this machine has gone through before it leaves the factory.

CE safety certificate, the "passport" to the European market.

Multi-rounds of machine running test, strict on quality control.

(video link https://mp.weixin.qq.com/s/fijaBn7u1jSSwfuhRp1EMQ)

Our company still actively responds to customer needs and expands overseas business during the COVID-19. The division of labor between departments is clear and responsibilities are assigned to people. From early customer development to order confirmation, from small parts assembly to overall running machine testing, from machine delivery to customer acceptance, after-sales engineers will continue to provide point-to-point timely after-sales service after acceptance to ensure smooth machine operation and efficient production. Every link is the crystallization of the collective wisdom of all colleagues of PIOTEC, which condenses everyone's hard work and sweat.

At present, we have a complete and mature inspection process, each card production machine will go through several rounds of commissioning, and quality testing before leaving the factory. The fastest response of demand, high-quality assembly, and the complete running process has shown the importance that PIOTEC attaches to customer needs and product quality control.

In the future, PIOTEC will continue to keep a strict eye on quality, strive to provide customers with high-quality and satisfactory service, and contribute to China's smart card manufacturing!