Visual recognition systems, also known as computer vision, are techniques that allow a computer or machine to simulate human vision and understand and interpret images and video. The main functions include:

Object identification: accurately identify the image or video objects, including people, animals, vehicles, buildings and so on. Scene comprehension: understanding a scene in an image or video, such as identifying whether it is indoor or outdoor, urban or rural.

Behavioral Analysis: the recognition and understanding of human or animal behavior, such as walking, running, jumping, etc.

Face recognition: accurate recognition of faces, used for identity verification or facial expression analysis.

Real-time processing: real-time processing of images and video for autopilot, video surveillance and other applications.

Deep Learning: through a large number of training data, improve the accuracy and robustness of recognition.

Smart cards and chips one of the key features of personalized machines is the ability to perform continuous mass production in a stable manner, The use of visual recognition system can improve the efficiency and quality of personalized operation, enhance the security and reliability of the chip, and facilitate the monitoring and management of chip quality and security.

Chip recognition: through the chip image acquisition and processing, can quickly and accurately identify the characteristics of the chip, convenient for subsequent personalized operation.

Chip personalization: through the chip image collection and processing, can determine the location and mode of personalized operation to ensure the accuracy and security of personalized operation.

Chip Quality Detection: through the chip image acquisition and processing, can detect chip appearance defects, welding quality and other issues, improve chip quality and reliability.

Anti-counterfeiting chip: Through the chip image collection and processing, can generate a unique chip identification code, and its chip for binding to prevent counterfeiting and tampering.

Chip traceability: Through the chip image acquisition and processing, can obtain the chip production and circulation information, convenient for chip quality and security monitoring and management.

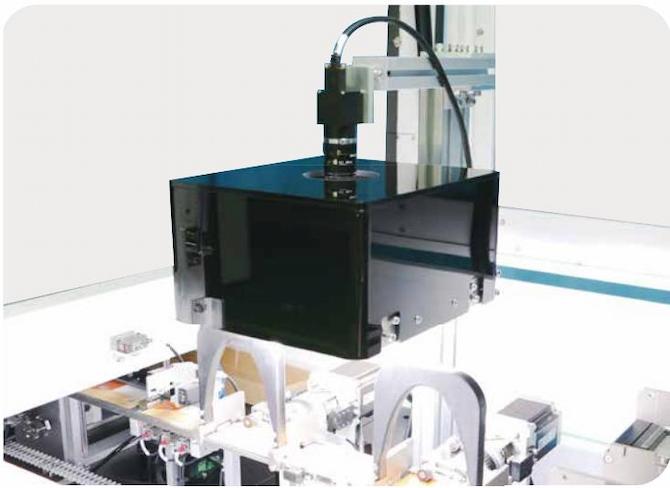

Taking the PTA -8500A High Speed SIM Card Personalization Machine as an example, the OCR check unit is set up. It includes 1 set of camera and 1 set of vision recognition system to realize the recognition and verification function of the card surface information (number, bar code, two-dimensional code, 25 code).

In the SCM3000 M2M Chip Personalization Machine, there is OCR check unit, which can recognize and check the chip surface information.

In the FPL6081 Bank card flexible line, also has the OCR check unit. It can realize the test of printed content, OCR can recognize digit, English letter, one-dimensional code and two-dimensional code, and can recognize the character of 2.5 mm word height at least.

And for the Important components of Smart Card Chip Module Encapsulatio Testing and Surface Defect Inspection Production line, Chip Module Inspection Machine CMI60000SA, Its main function is OCR detection.

Although visual recognition systems have made significant progress, there are still some challenges, such as dealing with complex scenes, understanding abstract concepts, and dealing with low-quality images or videos. In the future, with the further development of Technology, visual recognition system is expected to make greater breakthroughs in these areas.

To achieve a breakthrough in visual recognition systems, a large number of cases are necessary, that is, training data, to learn and understand patterns in images or videos. The training data can be labeled images or videos, which contain information we want the system to learn, such as the location of the object, type, and so on.

In deep learning, this approach is called supervised learning. Visual recognition systems can learn the mapping between input and output. Then, given a new unlabeled input, the system can predict the corresponding output. Collecting and tagging large amounts of training data is time-consuming and expensive. In these respects, companies that have been actively using OCR systems in device development have an advantage over mere university laboratories.